Picture this: a cosy evening by the fireplace, the warmth of a log burner spreading through the room.

However, the idyllic scene can quickly turn into a nuisance when the log burner starts to emit smoke. If you’re wondering, “Why is my log burner smoking?” you’re not alone.

In this comprehensive guide, we’ll explore the causes behind smoking wood burners and provide practical solutions to ensure you enjoy a clean and efficient heating experience.

Estimated reading time: 16 minutes

Table of contents

Understanding the Causes

Ensuring a smooth and efficient log burner experience involves addressing key factors that contribute to smoke-related issues.

The four main causes of smoking log burners:

- Poor-quality Wood

- Insufficient Airflow

- Cold Chimney (Cold plug)

- Excessive Creosote Buildup

Firstly, the choice of wood is paramount. The use of damp or unseasoned wood leads to incomplete combustion, generating smoke during the burning process.

Credit: Bevan, Log Burner Chat Group, Facebook

Optimal burning efficiency is achieved by investing in well-dried, seasoned wood with low moisture content below 20%. This not only minimises smoke production but also enhances heat output for a more effective and enjoyable heating experience.

Secondly, maintaining sufficient airflow is crucial for wood burning stoves. These appliances require a constant supply of oxygen to facilitate efficient combustion.

Regular checks and cleaning of vents, air inlets, and dampers are essential to prevent obstructions that could impede the inflow of oxygen, leading to incomplete combustion and increased smoke production. By ensuring these components are clean and operational, log burner owners can significantly reduce the risk of smoke-related issues.

Additionally, addressing the challenge of a cold chimney is vital for smoke-free burning. A cold chimney obstructs the upward flow of smoke, causing it to linger in the fireplace and escape into the room. Learning methods to pre-heat the chimney, such as using a small kindling fire before adding larger logs, enhances the draft and minimises smoke. Insulating the chimney or installing a chimney cap further helps retain heat, ensuring the chimney stays warm during operation.

Finally, proactive measures against excessive creosote buildup, a byproduct of burning wood, are essential. Regular chimney cleaning, whether through professional sweeps or DIY methods, prevents creosote accumulation, mitigating the risk of smoke issues and ensuring a safe and efficient log burner.

Choosing the Right Wood

Importance of Using Dry Wood

Unveiling the significance of using dry wood is essential for achieving a log burner that operates without emitting smoke.

Ensuring the moisture content of your wood is below 20% is crucial. To verify this, perform a moisture check by splitting the log and utilising prongs from a moisture meter at its center.

Dry wood plays a pivotal role in ensuring complete combustion, as it burns more efficiently and produces minimal smoke. Understanding the importance of this fundamental factor is key to a cleaner and more effective burning experience.

The best wood for less smoke:

- Ash

- Birch

- Hawthorn

- Hazel

- Oak

Proper storage and seasoning of wood are crucial components in maintaining its dryness. Discovering the best practices for storing and seasoning wood, such as keeping it well-ventilated and protected from the elements, are essential steps.

Top Tip: Look for wood with that is registered by the Ready To burn scheme, it should be sporting the logo which will ensure it has a moisture content below the recommended.

By incorporating these practices, log burner enthusiasts can guarantee a ready supply of dry wood, promoting optimal burning efficiency and contributing to a smoke-free environment.

Types of Wood to Avoid

Choosing the right type of wood is paramount for a log burner to function optimally, and understanding which types to avoid is equally crucial.

Certain woods, such as pine and other softwoods, release resin and sap when burned, leading to increased creosote buildup in the chimney. This not only poses a fire hazard but also contributes to smoking issues.

Related Articles:

Additionally, green or wet wood, which has a higher moisture content, results in incomplete combustion, generating more smoke and decreasing burning efficiency.

To ensure a clean and efficient log burner experience, it is advisable to avoid these types of wood and opt for well-seasoned, dry hardwoods like oak or ash, which burn cleanly and produce minimal smoke.

Proper Wood Storage

Proper wood storage is a fundamental aspect of maintaining a functional and efficient log burner, especially when aiming to prevent smoke-related issues. To guarantee a consistent and clean burning experience, it’s crucial to delve into best practices for storing firewood.

Start by selecting a well-ventilated and covered storage area, protecting the wood from external elements like rain and snow. Elevate the woodpile slightly to facilitate air circulation, preventing moisture absorption that can lead to difficult ignition and increased smoke production.

Arrange the firewood in a manner that allows for proper airflow between logs, promoting thorough drying. Opt for a loose stack rather than a tightly packed one, as this aids ventilation, reducing the risk of mold or decay.

A garage is an ideal location if you do not want to make a purpose built structure. It will provide good air flow as well as keep the logs dry.

By adhering to these best practices in proper wood storage, you not only ensure a readily available supply of well-seasoned and dry firewood but also contribute significantly to preventing smoking issues and promoting an efficient log burner operation.

Ensuring Proper Airflow

Significance of Sufficient Oxygen

Recognising the critical role of oxygen in the combustion process is key to achieving a smokeless log burner. Oxygen is a vital component that facilitates the burning of wood, allowing for efficient and complete combustion.

To ensure this essential element contributes to a clean burn, it’s imperative to maintain proper airflow within the log burner. Adequate oxygen intake prevents the production of excess smoke and unburned particles.

Understanding the significance of sufficient oxygen and implementing measures to sustain proper airflow not only enhances the overall efficiency of the log burner but also contributes significantly to a more environmentally friendly and enjoyable heating experience.

Cleaning Vents and Air Inlets

Maintaining unobstructed airflow in your log burner is essential for efficient combustion and to prevent smoking issues. Follow these step-by-step instructions to ensure your vents and air inlets are clean and free from obstructions.

- Safety First: Before starting the cleaning process, ensure the wood burner is completely cool to avoid burns. Also, wear protective gear, including gloves and safety goggles.

- Access the Vents and Air Inlets: Locate the vents and air inlets on your log burner. These are usually found on the front or sides. Consult your log burner’s manual if you’re unsure about their placement.

- Remove Debris: Use a soft brush or a vacuum cleaner with a nozzle attachment to gently remove any dust, ash, or debris that may have accumulated in the vents and air inlets. Ensure thorough cleaning to eliminate any potential blockages.

- Inspect for Damage: While cleaning, inspect the vents and air inlets for any signs of damage or wear. If you notice any issues, consider consulting a professional for repairs before using the wood burner again.

- Clean the Surrounding Area: Ensure the area around the vents and air inlets is clean. Remove any furniture, rugs, or other items that may obstruct airflow and contribute to smoking issues.

- Check for Smooth Operation: After cleaning, test the log burner to ensure that the vents and air inlets are operating smoothly. Open and close them to confirm unobstructed movement.

Regular cleaning of vents and air inlets is a simple yet effective way to maintain optimal airflow in your log burner, ensuring a clean burn and minimising the risk of smoke-related problems.

It could even be as simple as a birds nest that is blocking the air flow.

We would recommend a HETAS engineer to service your wood burning stove. You can find one here

Checking and Replacing Dampers

Discovering how dampers play a pivotal role in controlling smoke is crucial for maintaining a smoke-free log burner. Dampers are mechanisms that regulate airflow within the flue or chimney. Understanding their function is key to smoke control during the combustion process.

Periodic checks are essential to ensure dampers are operating optimally. If you notice signs of wear, rust, or difficulty in movement, it’s time to consider replacing them. Efficient dampers contribute to better control over the combustion process, reducing the likelihood of smoke issues.

Learning when to check and replace dampers ensures that your log burner operates at its best, providing a more efficient and enjoyable heating experience while reducing the risk of smoke-related concerns.

Addressing Chimney Temperature (Cold Plug)

Cold Chimney Issues

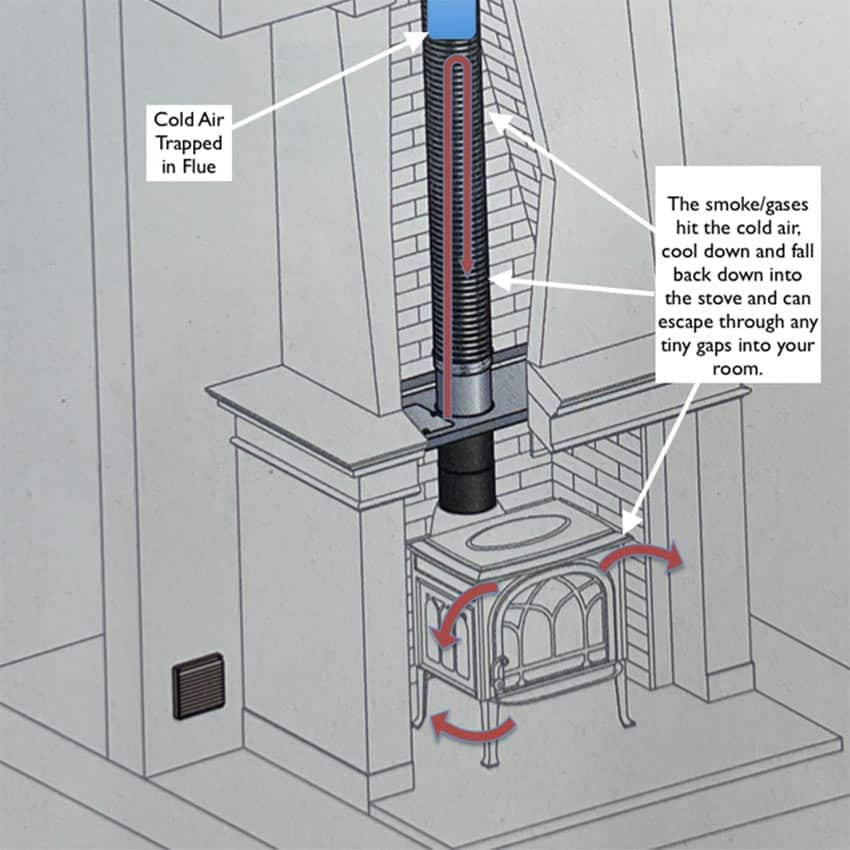

The phenomenon known as the “Cold Plug” in a chimney occurs when the chimney is cold, creating a barrier of cold air within.

When a stove is ignited under these conditions, the smoke generated by the fire encounters this cold plug, hindering its natural upward flow.

Instead of being directed outside, the smoke may find its way into the room, resulting in unintended and undesirable consequences.

Using a Pre-heating Method

To prevent the Cold Plug effect and ensure a smooth flow of smoke, it’s recommended to take a precautionary step. Before igniting a roaring fire, it’s advisable to lightly warm the flue.

Use the following methods to remove cold air in a chimney/ flue system:

- Blowtorch

- Hairdryer

- Candle

- Top down lighting method

- Flamer/ firelighter

- Door ajar/ loads of air

This preheating process helps eliminate the cold air barrier, allowing the smoke to ascend freely through the chimney.

By taking this simple measure, you can enhance the efficiency of your log burner, avoid smoke-related issues, and create a more enjoyable and controlled heating experience.

Lighting Best Practices

To prevent smoke pouring into the room.

To optimise the ignition process and minimise smoke, start by lighting just a firelighter. Once extinguished, ignite a fire using kindling only. Gradually introduce compressed log briquettes or small logs, allowing them to catch fire. After approximately 5 minutes, add the first log.

Credit: Clean Sweep Chimney Services

This method promotes a steady and efficient burn, significantly reducing the likelihood of smoke infiltrating your space.

Secondly, you can try the top down lighting method which invloves two logs at the bottom and kindling on top. If you burn smokeless coal, put that at the bottom, a couple of logs on top of that then kindling on top. Scrunch up newspaper into balls and light this too.

External Air Kits

So what do I do if nothing above has worked?

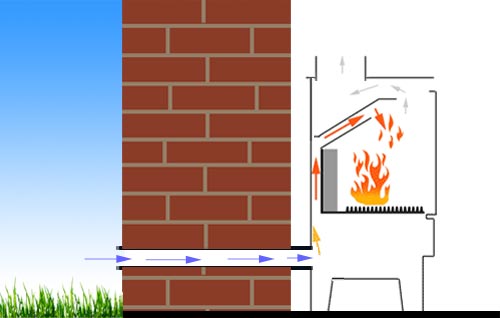

The majority of wood burning stoves have an availabile option for an external air kit. This kit functions by providing a direct external air supply to the log burner, ensuring that the combustion process has access to fresh air from outside the building rather than relying on indoor air.

This not only improves the efficiency of the burn but also contributes to better indoor air quality by preventing the log burner from drawing air from the room.

By facilitating a continuous flow of external air, the kit optimizes combustion, resulting in a cleaner and more effective log burning experience.

Additionally, this feature can be particularly beneficial in well-insulated homes, where maintaining proper air circulation is essential for both the performance of the log burner and the overall comfort of the living space.

The New Stove Smoke Effect

When introducing a new log burner into your space, it’s important to be aware that the initial burns play a crucial role in the curing process of the appliance’s paint.

After a few uses, you might observe a faint haze in the room. It’s essential to understand that this occurrence is a normal part of the paint curing process and poses no cause for concern.

It is recommended to have atleast 3 light burns to cure the stove paint. – It can take a couple of weeks until the smelly smoke doesn’t emit.

As the log burner undergoes its initial fires, the paint cures and bonds to the surface, emitting slight fumes in the process. This is a temporary and typically diminishes after the initial curing period.

Ensuring proper ventilation during these early burns can help reduce any inconvenience, allowing you to enjoy your log burner once the curing process is complete without any lingering concerns.

If this does carry on please do speak to the installer or seek professional help.

Twin Wall Flue System Smoke Troubles

A twin wall flue system, serving as a double-insulated flue pipe for wood burners in properties lacking a chimney, faces unique challenges due to its exterior installation.

This setup is more susceptible to environmental conditions, making it crucial to address potential smoking issues effectively. If you’re contending with a smoky log burner connected to a twin wall flue system, employing best practices becomes essential.

If you want to find out how to light a log burner with a twin wall flue system and prevent smoke from filling up the room please refer to the ‘Lighting Best Practices’ heading above.

Tackling Creosote Buildup

Understanding Creosote

Creosote, a residue formed during the combustion of wood, holds significant implications for the efficiency and safety of log burners.

As wood burns, it releases byproducts, including creosote, which can accumulate within the chimney or flue. This sticky substance poses a dual threat: it not only restricts proper airflow, leading to incomplete combustion and increased smoke production but also becomes a potential fire hazard due to its flammable nature.

Regular removal of creosote is paramount for a smokeless log burner. This preventive measure ensures that the chimney remains clear, minimising the risk of smoke-related issues and reducing the likelihood of a dangerous chimney fire.

Regular Chimney Cleaning

Maintaining a clean chimney is pivotal for the safe and effective operation of your log burner. Knowing how often to clean your chimney is crucial in preventing the buildup of creosote and other potential obstructions.

Generally, it is recommended to clean your chimney at least once a year, but the frequency may vary based on usage and the type of wood burned. A thorough cleaning process involves several steps, including inspecting the chimney for creosote buildup, removing any debris or blockages, and ensuring the flue and other components are clear for proper ventilation.

Find a local chimney sweep here

By adhering to these guidelines and adopting a regular chimney cleaning routine, you not only enhance the performance of your log burner but also mitigate the risk of chimney fires and ensure a safe and efficient heating experience.

Safety Measures

When your log burner is smoking, two crucial safety measures come into play. Firstly, ensure immediate ventilation by opening doors and windows to dissipate any accumulated smoke, safeguarding against potential health hazards.

Secondly, refrain from attempting to address the issue in close proximity to the log burner; instead, allow the area to clear and investigate the cause cautiously to prevent accidents or injuries.

Carbon Monoxide Concerns

Carbon monoxide (CO) poses a serious threat when using a log burner, emphasising the importance of understanding and addressing potential risks. It is a colourless, odourless gas that can be produced during incomplete combustion of wood in a log burner.

Safeguarding against its accumulation is paramount for the safety of individuals within the vicinity. Proper ventilation and regular maintenance of the log burner, including checking for any blockages or malfunctions, are crucial steps to mitigate the risk of carbon monoxide exposure.

Related Article:

Additionally, installing a carbon monoxide detector in the proximity of the log burner provides an added layer of safety, alerting occupants to any potential buildup of this harmful gas. By staying informed about carbon monoxide concerns and implementing preventive measures, log burner users can enjoy the warmth of their fireplace safely and confidently.

Proper Placement and Ventilation

Placing your log burner correctly and ensuring proper ventilation is fundamental for its safe and effective operation. Guidelines for the placement of a log burner typically involve installing it in a central location with adequate clearance from combustible materials.

The goal is to maximise heat distribution while minimising safety risks. Adequate ventilation is essential to ensure the efficient combustion of wood and the safe expulsion of byproducts. Positioning the log burner in a well-ventilated area and avoiding airtight spaces prevents the buildup of harmful gases, including carbon monoxide.

Find a professional to install/ service your wood burning stove here (or use us)

It’s crucial to follow manufacturer recommendations for both placement and ventilation, as these guidelines are designed to optimise the log burner’s performance while prioritising the safety of those enjoying its warmth.

Conclusion

In conclusion, enjoying a smoke-free log burner is not only achievable but essential for a pleasant and efficient heating experience.

By understanding the causes, implementing practical solutions, and prioritising maintenance, you can ensure your log burner remains a source of warmth without the inconvenience of smoke.

If you liked our article or would like ot discuss this topic with a professional, we can be contacted via phone on 0118 970 1717 or via email info@bonfire.co.uk

FAQs

The best wood for a log burner is dry hardwood, such as oak or ash, as it burns efficiently and produces less smoke.

No, using green or wet wood leads to incomplete combustion, increased smoke, and can contribute to creosote buildup.

Regular chimney cleaning is recommended annually, or more frequently if you notice significant creosote buildup.

Basic troubleshooting, like checking airflow and using dry wood, is safe. However, for complex issues, seek professional assistance from a HETAS engineer.

Yes, there are regulations to control emissions. Ensure your log burner complies with local environmental standards such as Defra.